Thanks to this screen, your monitor consumes less energy when the computer is inactive.

To restart navigation, simply click with the mouse.

PRODUCTS

Find what you need among more than 11.000 products.

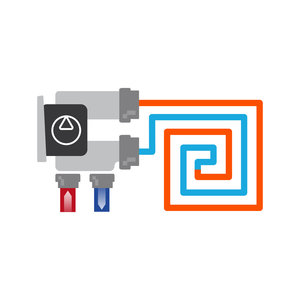

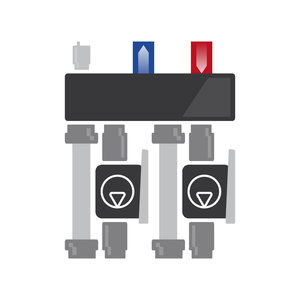

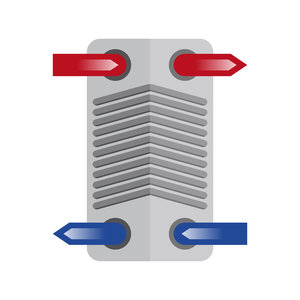

Manifolds

Manifolds for heating and cooling systems, boxes, ball valves, zone valves and accessories.

01

Modular manifolds EASY•RADIANT

02

Brass-rod manifolds

03

Stainless steel manifolds

04

Technopolymer manifolds

05

Coplanar manifolds

06

Cabinets

07

Terminals for manifolds

08

Air vent valves

09

Brackets

10

Bypass valves

11

Fittings and plugs

12

Spare parts and complementary items

13

Ball valves

14

Zone valves